Ball Valves Manufacturers

VALVE Categories

Contact Us

sales@tycovalve.com+86-15961836110108 Meiyu Road, Xinwu District, Wuxi, Chinamanufacturer & supplier of high-quality ball valves, produce ball valves of various standards, such as ANSI 、DIN、EN、JIS ball valves, etc.

Worm gear switch flange ball valve CL600

Stainless Steel Extended Rod Flange Ball Valve

pneumatic V-type regulating ball valve

Pneumatic Discharge Ball Valve Inclined

DIN Flange Ball Valve Full bore Stainless Steel

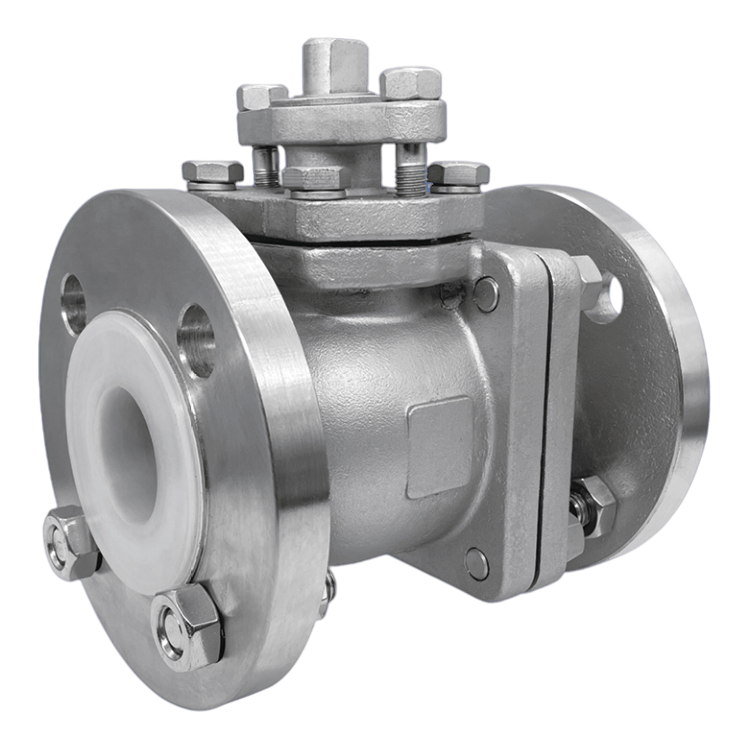

stainless steel Lined ball Valve PFA/FEP/PTFE

Electric Flanged Ball Valve Actuator CF8/PTFE/ClASS 150

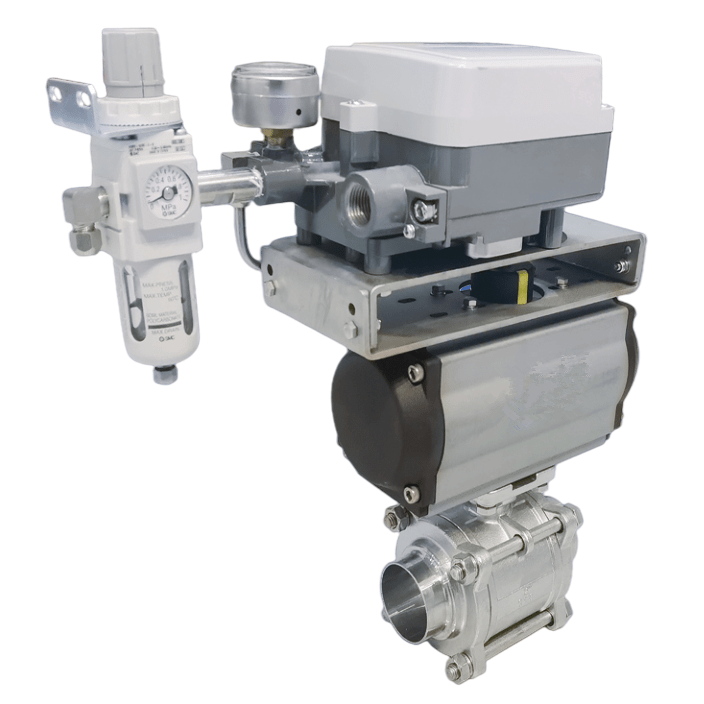

3PC threaded ball valve Electric Actuator 1000WOG&2000WOG

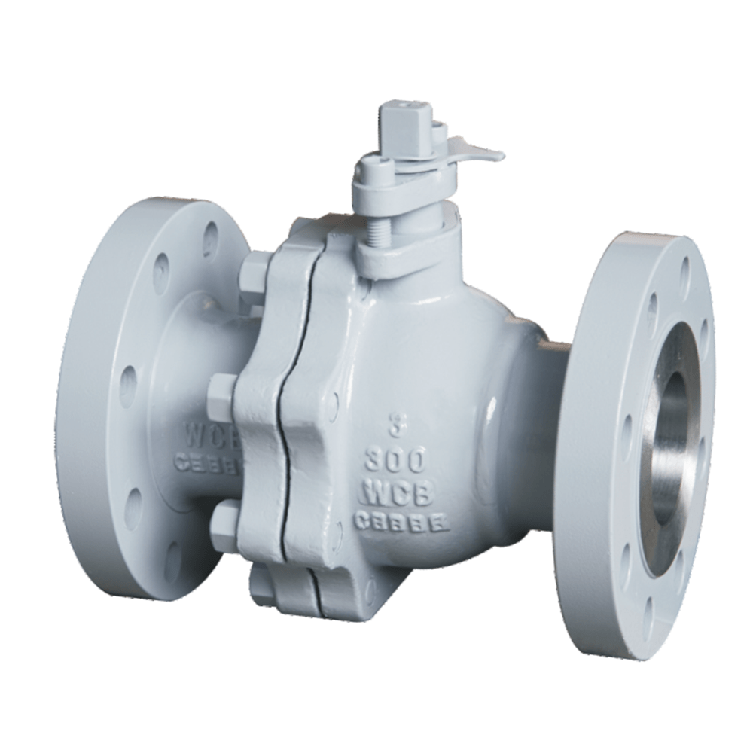

ANSI Class 300 Flanged Ball Valve Gear Operated/handle

Metal Seated Flanged Ball Valve with ISO 5211 upper flange

pneumatic welded three piece ball valve-Stainless steel

High Vacuum(Pressure)Ball Valve

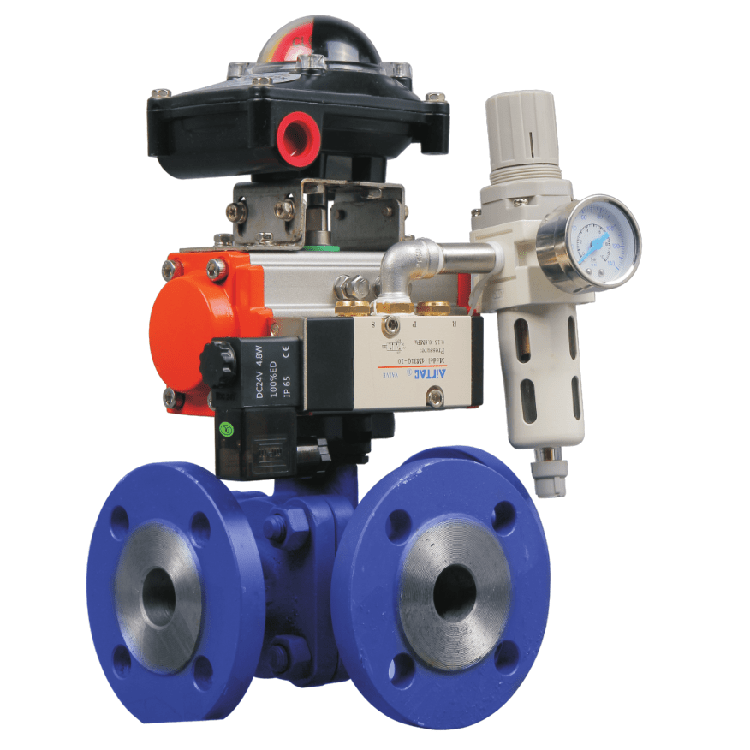

Pneumatic three way ball valve

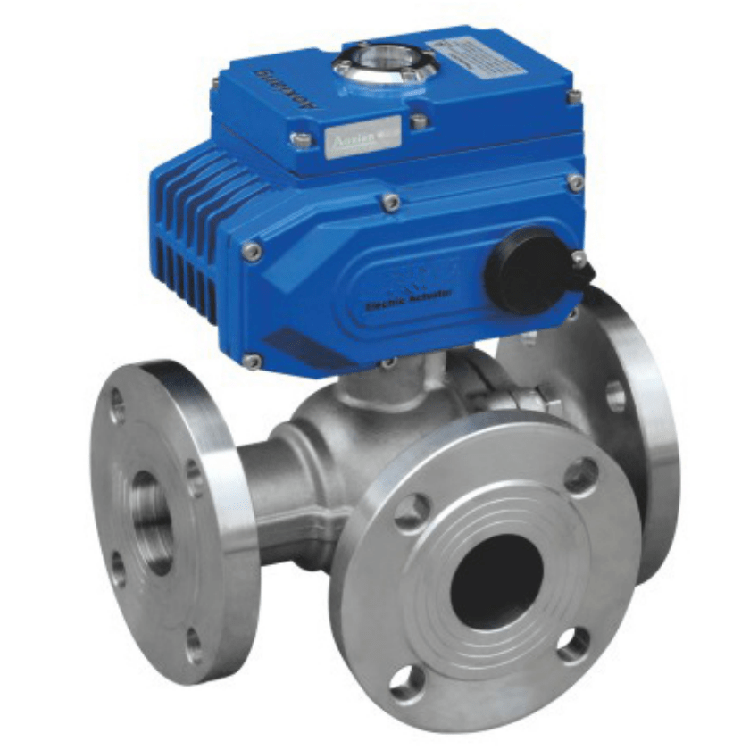

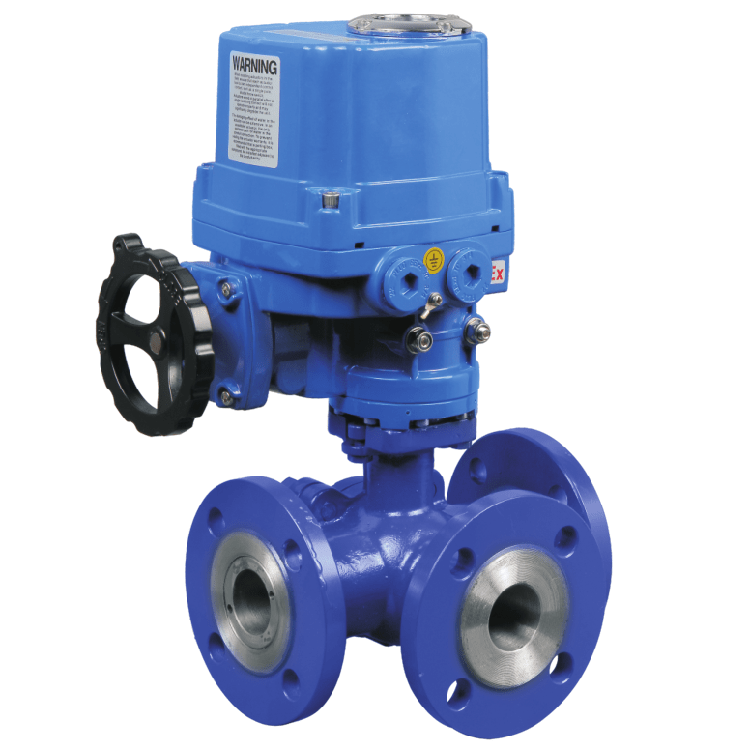

electric three-way ball valve Adjustment/Switch

class150 electric ball valve

ANSI class 600 ball valve Flanged

Pneumatic three-way Flange ball valve

Electric three-way flanged ball valve Cast steel

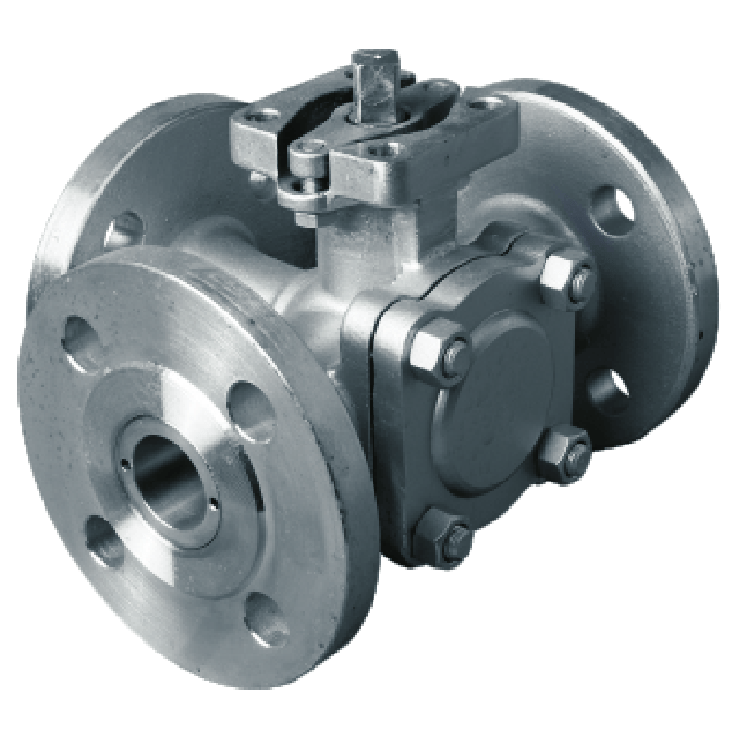

flanged three-way ball valve with platform/bare shaft

Stainless steel three-way flanged ball valve

V-port Segment Pneumatic Ball Valve (Wafer)

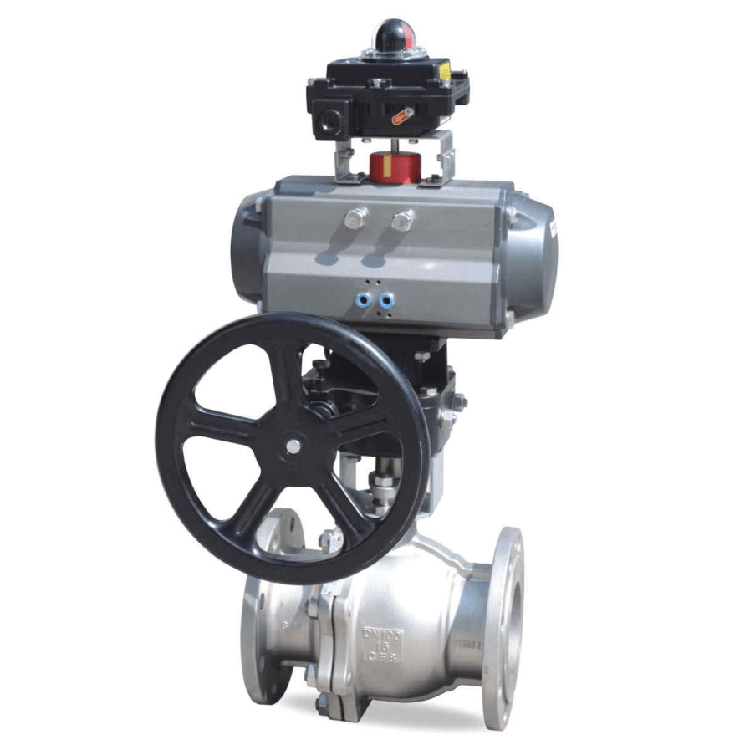

Pneumatic manual flanged ball valve

4-way flange ball valve Manufacturer-Stainless/Carbon Steel

KS Flange Ball Valve – stainless steel manual handle

ANSI Class 150 Pneumatic Ball Valve Flanged – Actuator

Flanged JIS 20K Ball Valve-stainless steel handle operation

JIS 10K Flanged Ball Valve Stainless Steel/cast steel

ANSI Class 150 Flanged Ball Valve

PTFE PFA lined pneumatic ball valve with actuator

ASIAV Ball Valves Series

The ball valves is a valve that uses a ball with a circular channel as the opening and closing part, and the ball rotates with the valve stem to realize the opening and closing action. The opening and closing part of the ball valve is a ball with holes, which rotates around the axis perpendicular to the channel, so as to achieve the purpose of opening and closing the channel. The ball valves is mainly used for opening and closing pipes and equipment media.

We are a manufacturer & supplier of high-quality ball valves, we can produce customized ball valves of various standards, such as American standard ball valves, Japanese standard ball valves, European standard ball valves, etc.Ball valves include: floating ball valve, fixed ball valve, rail ball valve, V-shaped ball valve, three-way ball valve, stainless steel ball valve, cast steel ball valve, forged steel ball valve, ash unloading ball valve, sulfur resistant ball valve, pneumatic ball valve, electric ball valve, ferrule ball valve and welded ball valve.

According to the classification of shell / main body materials, ball valves can be divided into:

1. Metal ball valves: such as carbon steel ball valves, alloy steel ball valves, stainless steel ball valves, cast iron ball valves, titanium alloy ball valves, Monel ball valves, copper alloy ball valves, aluminum alloy ball valves, lead alloy ball valves, etc.

2. Metal body lined ball valves: such as rubber lined ball valves, fluorine lined ball valves, lead lined ball valves, plastic lined ball valves and enamel lined ball valves.

3. Non metallic ball valves: such as ceramic ball valves, glass ball valves and plastic ball valves.

According to the classification of structure / standard and driving mode, ball valves can be divided into:

1. Structure: single piece ball valve, two piece ball valve, three piece ball valve, floating ball valve, fixed ball valve, v-ball valve

2. Standard: American standard ball valve, Japanese standard ball valve

3. Driving mode: electric ball valve, handle ball valve, worm wheel ball valve, pneumatic ball valve and hydraulic ball valve

Ball valve, the valve whose opening and closing parts (ball) are driven by the valve stem and rotate around the axis of the ball valve. It can also be used for fluid regulation and control. The V-type ball valve with hard seal has a strong shear force between its V-type ball core and the metal valve seat of hardfacing hard alloy. It is especially suitable for medium containing fiber, small solid particles, etc. The multi-way ball valve can not only flexibly control the confluence, diversion and flow direction switching of the medium on the pipeline, but also close any channel to connect the other two channels. This type of valve shall be installed horizontally in the pipeline. The ball valve is divided into pneumatic ball valve, electric ball valve and manual ball valve according to the driving mode.

1、 Wear resistance; Since the valve core of the hard seal ball valve is alloy steel spray welded,

Two piece ball valve

Three piece ball valve

The sealing ring is made of alloy steel, so the hard seal ball valve will not produce too much wear when opening and closing. (its hardness coefficient is 65-70):

2、 Good sealing performance; Since the seal of hard seal ball valve is manually ground, it can not be used until the valve core and seal ring are completely matched. So its sealing performance is reliable.

3、 Light switch; Since the bottom of the sealing ring of the hard sealed ball valve is tightly held with the valve core by the spring, the switch is very light when the external force exceeds the preload of the spring.

4、 Long service life: it has been widely used in petroleum, chemical industry, power generation, paper making, atomic energy, aviation, rocket and other departments, as well as people’s daily life.

The pneumatic ball valve is simple and compact in structure, reliable in sealing and convenient in maintenance. The sealing surface and spherical surface are always closed, and are not easily eroded by the medium. It is easy to operate and maintain. It is suitable for general working media such as water, solvent, acid and natural gas. It is mainly used to cut off or connect the medium in the pipeline, and can also be used for fluid regulation and control.

Compared with other types of valves, pneumatic ball valves have the advantages of angular stroke output torque, rapid opening, stable and reliable, wide application, and the following:

1. The thrust bearing reduces the friction torque of the valve stem, which can make the valve stem operate smoothly and flexibly for a long time.

2. Anti static function: a spring is set between the ball, the valve stem and the valve body to export the static electricity generated during the switching process.

3. Because PTFE and other materials have good self-lubricating property and small friction loss with the ball, the service life of the pneumatic ball valve is long.

4. Small fluid resistance: pneumatic ball valve is the one with the smallest fluid resistance in all valve classifications. Even for reduced diameter pneumatic ball valve, its fluid resistance is quite small.

5. Reliable sealing of the valve stem: since the valve stem only rotates without lifting, the packing seal of the valve stem is not easy to be damaged, and the sealing capacity increases with the increase of the medium pressure.

6. Good sealing performance of the valve seat: the sealing ring made of elastic materials such as polytetrafluoroethylene is easy to seal, and the sealing capacity of the pneumatic ball valve increases with the increase of the medium pressure.

7. The fluid resistance is small, and the full-diameter ball valve basically has no flow resistance.

8. Simple structure, small volume and light weight.

9. Tight and reliable. It has two sealing surfaces, and the sealing surface materials of the ball valve are widely used in various plastics, with good sealing performance and complete sealing. And has been widely used in vacuum systems.

10. Easy operation, quick opening and closing, only 90 ° rotation from full opening to full closing, convenient for remote control.

11. The maintenance is convenient, the structure of the ball valve is simple, the sealing ring is generally movable, and the disassembly and replacement are relatively convenient.

12. When the valve is fully opened or fully closed, the sealing surface of the ball and the valve seat is isolated from the medium. When the medium passes through, the valve sealing surface will not be eroded.

13. It has a wide range of applications, ranging from a few millimeters to a few meters, and can be applied from high vacuum to high pressure.

14. The ball valve can be used in the medium with suspended solid particles due to its wiping property during opening and closing.

15. High processing accuracy, high cost, not suitable for use in high temperature. If there are impurities in the pipeline, it is easy to be blocked by impurities, resulting in the valve cannot be opened.

We are a valve manufacturer, if you need other valve types, you can select or search what you need through our valve selection interface, or you can send us an email