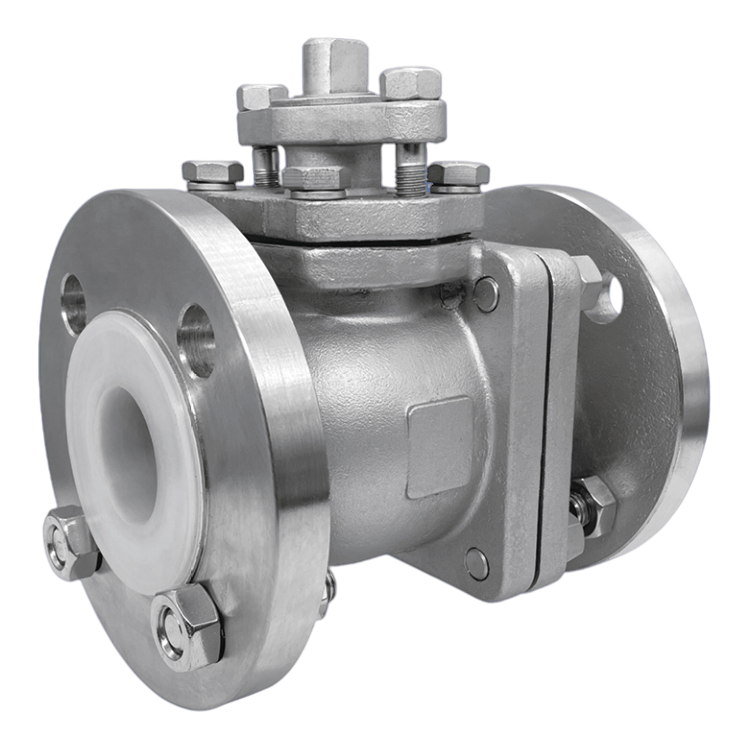

Stainless steel lined ball valves open mainly handle or Gear Operated, if you need automatic control, we can assemble pneumatic or electric actuators.

China Lined ball Valve PFA/FEP/PTFE

Although stainless steel material has a very strong corrosion resistance, but lining PFA/FEP/PTFE will make the corrosion resistance of the valve to improve again, double protection acid, alkali attack on the pipeline valve.

Stainless Steel Flourine Lining Ball Valve advantage /ANIS class 150 Lined ball Valve

- The fluid resistance is small, and its resistance coefficient is equal to that of the pipe section with the same length.

- Simple structure, small volume and light weight.

- It is tight and reliable. Plastic is widely used as the sealing surface material of the ball valve, with good sealing performance. It has also been widely used in the vacuum system.

- Easy operation, quick opening and closing, only 90 ° rotation from full opening to full closing, convenient for remote control.

- The maintenance is convenient, the ball valve structure is simple, the sealing ring is generally movable, and the disassembly and replacement are relatively convenient.

- When the valve is fully opened or fully closed, the sealing surface of the ball and the valve seat is isolated from the medium. When the medium passes through, the sealing surface of the valve will not be eroded.

- Wide range of application, the diameter is from a few millimeters to a few meters, and can be applied from high vacuum to high pressure

PFA/FEP/PTFE Lined ball Valve manufacturers

Connection type: flange

Switching methods: handle, Gear Operated, electric, pneumatic

Liner: PTFE, FEP, PFA, etc

Standards :ANSI, JIS, EN, DIN

Material: stainless steel 304/316, cast steel

floating ball valve

ANSI Class 150 Stainless Steel Flourine Lining Ball Valve Main External and Connecting Dimensions

| NPS | D1 | d | K | D | C | f | N-OZ | L | H E | E |

| 1/2″ | 15 | 34.9 | 60.3 | 90 | 14 | 1 | 4-16 | 108 | 79 | 125 |

| 3/4″ | 20 | 42.9 | 69.9 | 100 | 16 | 1 | 4-16 | 117 | 82 | 125 |

| 1″ | 25 | 50.8 | 79.4 | 110 | 16 | 1 | 4-16 | 127 | 102 | 155 |

| 1 1/4″ | 32 | 63.5 | 88.9 | 115 | 18 | 2 | 4-16 | 140 | 106 | 155 |

| 1 1/2″ | 38 | 73 | 98.4 | 125 | 18 | 2 | 4-16 | 165 | 128 | 240 |

| 2″ | 50 | 92.1 | 120.7 | 150 | 18 | 2 | 4-19 | 178 | 135 | 240 |

| 2 1/2″ | 65 | 104.8 | 139.7 | 180 | 20 | 2 | 4-19 | 190 | 145 | 280 |

| 3″ | 78 | 127 | 152.4 | 190 | 22 | 2 | 4-19 | 203 | 160 | 320 |

| 4″ | 98 | 157.2 | 190.5 | 230 | 24 | 2 | 8-19 | 229 | 180 | 320 |

| 5″ | 123 | 185.7 | 215.9 | 255 | 26 | 2 | 8-22 | 356 | 252 | 530 |

| 6″ | 148 | 215.9 | 241.3 | 280 | 28 | 2 | 8-22 | 394 | 285 | 630 |

| 8″ | 198 | 269.9 | 298.5 | 345 | 30 | 2 | 8-22 | 457 | 385 | 800 |

| 10″ | 248 | 323.8 | 362.0 | 405 | 34 | 2 | 12-25 | 533 | 485 | |

| 12″ | 298 | 381.0 | 431.8 | 485 | 36 | 3 | 12-25 | 610 | 545 | |

| 14 | 348 | 412.8 | 476.3 | 535 | 44 | 3 | 12-25 | 686 | 635 |

Features

1. The valve stem has an anti-static setting

2. The valve stem is designed with an anti-disengagement device.

3. There is a pressure relief hole design on the ball groove of the steel ball.

4. Adopt ISO 5211 direct installation actuator platform design.