Wafer Butterfly Valves Manufacturers

VALVE Categories

Contact Us

sales@tycovalve.com+86-15961836110108 Meiyu Road, Xinwu District, Wuxi, ChinaWafer butterfly valve means that the butterfly valve body has no flange, and the flanges on both sides of the pipeline clamp the butterfly valve to fix it.

JIS 10K butterfly valve Wafer

High temperature butterfly valve Flange&wafer

with lock butterfly valve Worm gear Operated Key

Signal feedback butterfly valve with limit switch

JIS 20K Triple Offset Wafer butterfly valve-metal seated

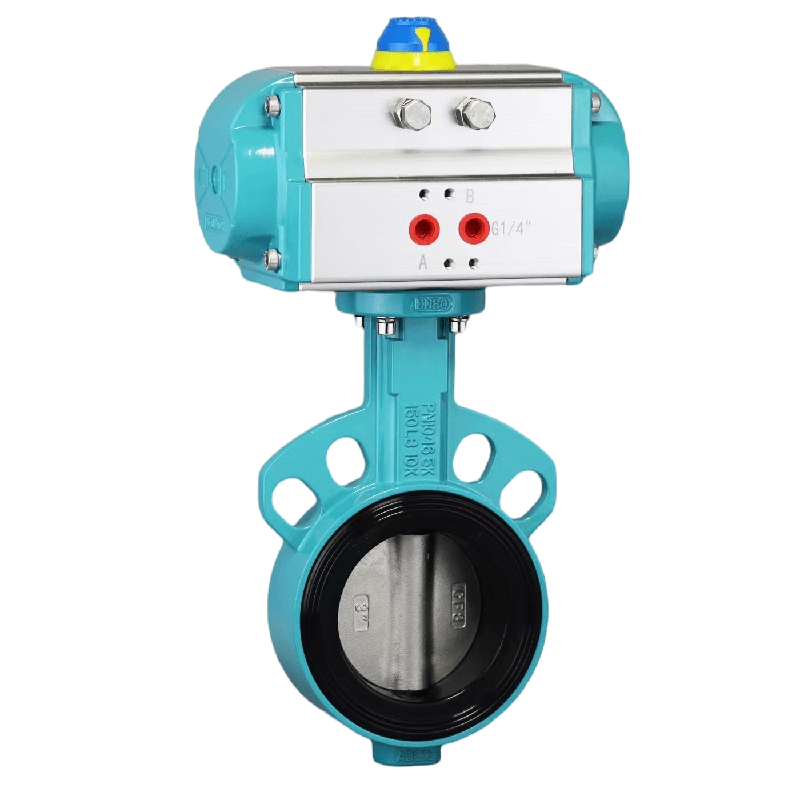

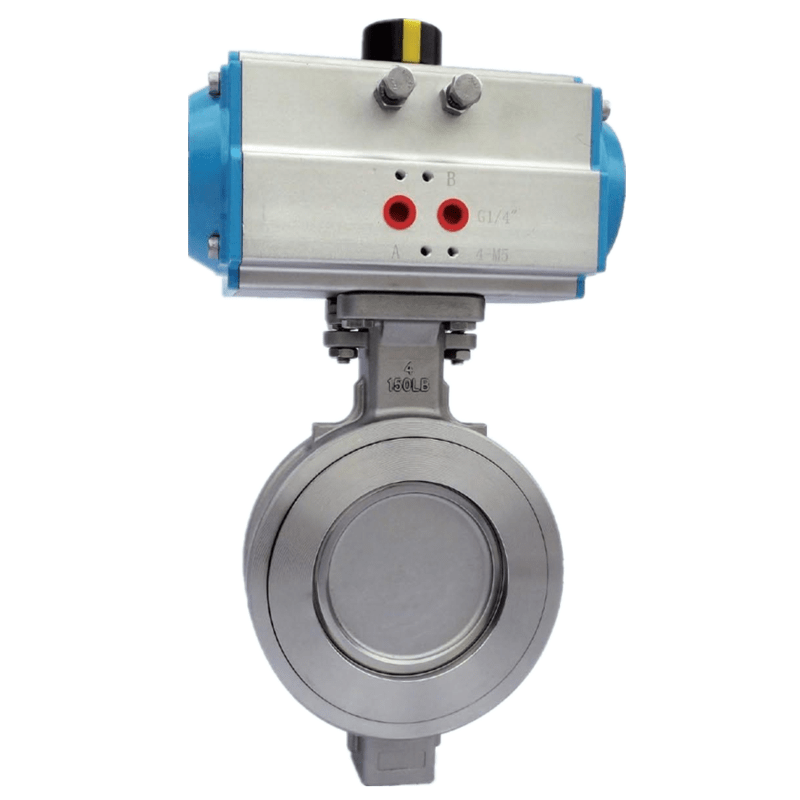

Pneumatic wafer butterfly valve

Wafer with bare shaft high performance butterfly valve – platform

high performance wafer pneumatic buttefly valve

Handle lever operated High Performance butterfly valve

High Performance butterfly valve bare shaft carbon steel

high performance wafer butterfly valve worm gear box operated

ASIAV Wafer Butterfly Valves Series

The butterfly plate of the wafer type butterfly valve is installed in the diameter direction of the pipe. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis with a rotation angle of 0 ° – 90 °, which can play the role of flow regulation. When the butterfly plate rotates to 90 °, the valve reaches the maximum opening.

The wafer butterfly valve is simple in structure, small in volume and light in weight, and is composed of only a few parts. Moreover, the valve can be opened and closed quickly only by rotating 90 °, and the operation is simple. At the same time, the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body, so the pressure drop generated by the valve is very small, so it has good flow control characteristics. Butterfly valve has two sealing types, elastic soft seal and metal seal. Elastic soft seal valve, the sealing ring can be embedded on the valve body or attached to the periphery of the butterfly plate.

Valves with metal seals generally have a longer service life than those with elastic seals, but it is difficult to achieve complete sealing. Metal seal can adapt to high working temperature, while elastic soft seal has the defect of being limited by temperature.

If the butterfly valve is required to be used for flow control, the main thing is to correctly select the size and type of the valve. The structure principle of butterfly valve is especially suitable for making large-diameter valves. This type of valve shall be installed horizontally in the pipeline.

Commonly used butterfly valves include wafer butterfly valves and flange butterfly valves. The wafer type butterfly valve connects the valve between two pipe flanges with stud bolts. The flange type butterfly valve has flanges on the valve, and the flanges at both ends of the valve are connected to the pipe flanges with bolts.

purpose

Used for gas pipeline in sulfuric acid industry: inlet and outlet of blower in front of furnace, inlet and outlet of relay fan, electric demister series and connecting valve, inlet and outlet of S02 main blower, converter regulation, inlet and outlet of preheater, etc. and gas cut-off.

It is used in the sulfur burning, conversion and dry absorption sections of the sulfur based sulphuric acid production system. It is the first choice brand of valves for the sulfur based sulphuric acid production unit. It is considered by the majority of users as a butterfly valve with good sealing performance, light operation, side corrosion, high temperature resistance, convenient operation, flexible operation, safe and reliable use, and has been widely promoted and used.

It is also widely used in the pipeline of SO2, steam, air, gas, ammonia, CO2 gas, oil, water, brine, alkali liquor, seawater, nitric acid, hydrochloric acid, sulfuric acid, phosphoric acid and other media in the chemical, petrochemical, smelting, pharmaceutical, food and other industries as a regulating and intercepting device.

Structural features of wafer butterfly valve

① The unique design of three-way eccentric makes no friction transmission between the sealing surfaces and extends the service life of the valve.

② An elastic seal is generated by the torque.

③ The ingenious wedge-shaped design enables the valve to have the automatic sealing function of getting tighter and tighter as the valve is closed, and the sealing surfaces have compensation and zero leakage.

④ Small size, light weight, light operation and easy installation.

⑤ Pneumatic and electric devices can be configured according to user requirements to meet the needs of remote control and program control.

⑥ The material of the replacement parts can be applicable to various media, and the lining can be anticorrosive (lining F46, gxpp, Po, etc.).

⑦ Continuous structure diversification: butt clamp, flange and butt welding.

structural style

(1) Central sealing butterfly valve (2) single eccentric sealing butterfly valve (3) double eccentric sealing butterfly valve (4) triple eccentric sealing butterfly valve

Sealing surface material

(1) Soft seal butterfly valve. 1) The sealing pair is composed of a non-metallic soft material and a non-metallic soft material. 2) The sealing pair is composed of metal hard material and non-metal soft material. (2) Metal hard seal butterfly valve. The sealing pair is composed of a metal hard material and a metal hard material.

Sealing form

(1) Forced sealing butterfly valve 1) elastic sealing butterfly valve. The sealing specific pressure is generated by the elasticity of the valve seat or valve plate when the valve plate presses the valve seat when the valve is closed. 2) External torque sealing butterfly valve. The seal specific pressure is generated by the torque applied to the valve shaft. (2) Pressurized sealing butterfly valve. The sealing specific pressure is generated by the charging of the spring sealing element on the valve seat or valve plate. (3) Automatic sealing butterfly valve. The sealing specific pressure is automatically generated by the medium pressure.

working pressure

(1) Vacuum butterfly valve. Butterfly valve with working pressure lower than atmospheric pressure of standard reactor. (2) Low pressure butterfly valve. Butterfly valve with nominal pressure PN < 1.6Mpa. (3) Medium pressure butterfly valve. Butterfly valve with nominal pressure PN of 2.5-6.4mpa. (4) High pressure butterfly valve. The nominal pressure PN is 10. 0-80.0mpa butterfly valve. (5) Ultra high pressure butterfly valve. Butterfly valve with nominal pressure PN > 100MPa.

working temperature

(1) High temperature butterfly valve. t> 450 ° C butterfly valve (2) medium temperature butterfly valve. Butterfly valve with 120 C < T < 450 ℃. (3) Normal temperature butterfly valve. – 40C < T <; Butterfly valves at 120 ° C. (4) Low temperature butterfly valve. A butterfly valve with 100 < T < 40 ° C. (5) Ultra low temperature butterfly valve. T < 100 ° C butterfly valve.